Ifakwe ngobuchwepheshe obugxile futhi obugxile kakhulu, lezi zindaba zokushisa zinikezela ngezinsizakalo ezingenakuqhathaniswa futhi zize nezindleko zokulungiswa okuphansi. Imishini yokucindezela ye-Xinhong EasyTrans ™ isetshenziswa kabanzi embonini yokuphrinta ngenxa yokusetshenziswa kwayo okuhlukahlukene kanye nokuphrinta okuseqophelweni eliphezulu kusebenza. Kungakhathalekile ukuthi ungaphrinta kuliphi indawo, lokhu kucindezela ukushisa kungenza kahle ngaphezu kwazo zonke izinhlobo zezindawo ezingaphezulu. Le mishini yokushisa ingahle isetshenziswe ezindaweni eziningana njengokukhiqiza izitshalo, izindawo zokuhlala, imisebenzi yokwakha, izitolo zokuthengisa, izindlu zokuphrinta, izindlu eziningi ngenxa ye-ink yokuphrinta yebanga asebenza nayo.

Platen Platen Outomatic Heat Press (Model # B2-2n Smart)yinguqulo ye-v3.0 futhi ivuselelwa ngokususelwa ku-B2-2n eyisisekelo futhi ibe lula futhi inobuhlakani.

Lo mshini wokushisa we-elekthronikhi ungumshini ongaphezulu we-the-the-the-the-the-umugqa uma kukhulunywa ngokukhiqizwa kwesisindo ngamazinga aphezulu. Le yunithi ingaphatha noma yini - izingubo ezinkulu noma ezincane, amathayili amaningi we-ceramic, nezinye izigatshana eziningi. Akudingi umoya ocindezelwe, okwenza kube lula ngokwengeziwe. Ifaka ukusebenza kahle kakhulu & nengcindezi enhle kakhulu, ingasebenza ngezindlela ezigcwele ze-auto, noma ngezindlela ze-semi-auto. Ngama-time-timers kanye nezinyawo, abasebenzisi bangenza umsebenzi ophelele. Le mishini yokushisa okushisa okulula i-Smart Level Heat inamapuleti aphansi futhi ingaba yi-semi-auto noma izenzakalelayo ngokugcwele ekushintsheni okukodwa. Lesi simo sokushisa sikagesi sifakiwe nge-HMI / PLC Gauge, ngakho-ke umsebenzisi angalawula isivinini sawo sokuhambisa, futhi akwazi nokudubula inkathazo lapho kudingekile. If user need to work with different size substrates, quick optional platen would be a good proposals, we've different platens and video uploaded on YouTube, here is the link,https://www.youtube.com/watch?v=t9yzxo6qkbk

Njengomshini wokushisa wokushisa okuzenzakalelayo we-Ultra othomathikhi (imodelisales@xheatpress.comnoma i-whatsapp / i-WeChat Contact by 86-150 6088 0319.

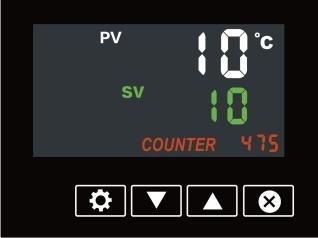

Isingeniso sePontrol Panel Isingeniso

Iwindi lephaneli yokulawula

I-P-1: Ukulungiswa kokushisa

Inkinobho yokuthinta inkinobho, qhubeka nenkinobho ye-▲ / ▼ ukusetha izinga lokushisa oyifunayo.

I-P-21: Isikhathi 1 sokusetha (Pre-Press)

Inkinobho yokuthinta inkinobho, qhubeka nenkinobho ye-▲ / ▼ ukusetha isibali sikhathi esifunekayo 1

I-P-22: Isikhathi 2 sokusetha (umshini wokushisa)

Inkinobho yokuthinta, Qhubeka nenkinobho ye-▲ / ▼ ukusetha isibali sesikhathi 2

● Ithiphu: Setha idatha ye-P-22 ku-0 uma i-Timer 2 ayidingekile

I-P-23: I-Timer 3 Set (Ukuqiniswa Cindezela)

Inkinobho yokuthinta, Qhubeka nenkinobho ye-▲ / ▼ ukusetha isibali sesikhathi 3

● Ithiphu: Setha idatha ye-P-23 ku-0 uma i-Timer 3 ayidingeki

I-P-3: ° C / ° F izinga lokushisa lokufunda

Inkinobho ethi TOUCH SET, Qhubeka nenkinobho ye-▲ / ▼ ukusetha okufundwayo

I-P-4: Ukuhlelwa Kwengcindezelo

Inkinobho yokuthinta, qhubeka nenkinobho ye-▲ / ▼ ukusetha ingcindezi oyifunayo

● Ithiphu: Ingcindezi inyuka njengoba idatha ye-P-4 iyanda.

I-P-5: Ukuhlelwa kwesikhathi sokulinda kwemodi

Inkinobho yokuthinta, Qhubeka nenkinobho ye-▲ / ▼ ukusetha isibali sikhathi sokulinda.

● Ithiphu: Umshini ungena kwimodi yokulinda uma kungasebenzi isikhathi se-P-5 futhi ufunde.

Ukushisa Plasen kumisa ukufudumeza nokuphola phansi. Inkinobho yokulawula ukuthinta umshini wokuvuka nokushisa okushisa okushisa.

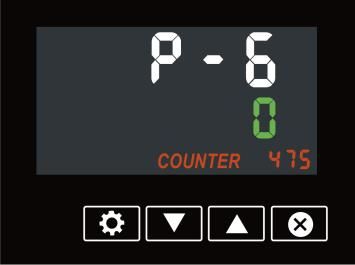

I-P-6: Shintsha ama-Multi-Timer

Inkinobho yokuthinta inkinobho, qhubeka nenkinobho ye-▲ / ▼ ukusetha i-multi-timer, inkinobho yokuthinta ukuqedela zonke izilungiselelo.

ICEBISO: I-P-6 yokufunda-ukuphuma ku-0, ibhekisa kwisikhathi esisodwa esisetshenzisiwe.

ICEBISO: I-P-6 Ukufundwa ku-1, kubhekiselwa ku-Triple Timers, imvamisa isetshenziswa epuletini elilodwa. (Ie Timer 1 - Isikhathi 2 - Isikhathi 3)

ICEBISO: I-P-6 yokufunda-ukuphuma ku-2, ibhekisa ku-Triple Timers futhi iphindaphindwe, imvamisa isetshenziswa kumamakethe amabili. (Ie Timer 1 - Isikhathi 1 - Isikhathi 2 - Isikhathi 2 - Timer 3 - Timer 3)

Isikhundla se-2.inial

Ohlangothini lwesobunxele njengesikhundla sokuqala, iminwe eyisibili yomsebenzisi chofoza izinkinobho zokuqala (izinkinobho eziluhlaza) Thola imiphumela emi-2.

I-1.Heat Plater ibuyela ohlangothini lwesobunxele ngemuva kokuchofoza, ngokulandelayo ngokuchofoza kwenza ukushisa kokushisa kuvalele phansi.

2.Ukuvala iplanethi phansi uma sekuvele kuseceleni kwesokunxele.

Isingeniso se-3.Operation

Imodi ye-Semi-auto (switch to Manual), Izinkinobho eziluhlaza zilawula ukufudumeza okuvaliwe bese ziphakamisa, ukuhambisa izikhala zokushisa ukushisa okushibhile phakathi kwesiteshi kwesokunxele nangakwesokudla.

Imodi ezenzakalelayo (Shintshela ku-Auto), izinkinobho eziluhlaza chofoza ukuqala imodi ezenzakalelayo ngohlelo lokulawula. (Ithiphu: I-Pedal ikhutshaziwe kwimodi ye-auto.)

Imodi ye-4.Day Fight Chofoza

I-Heat Plasen ivala lapho iminwe embaxambili ichofoza izinkinobho eziluhlaza, iminwe iyavunyelwa ukuthi ikhishwe ngaphandle kokuthi kuvalwe ukufudumala kwepuleti ngokuqinile, ngaphandle kwalokho kuzovuka.

Inkinobho ye-5.Quick Reser

Misa okwesikhashana inkinobho yokukhishwa, ukuvala izitobha kanye neplanethi yokushisa kuphakama. Ngemuva kwenkinobho yokukhishwa kusethwe kabusha futhi izinkinobho eziluhlaza zichofozwa, ukushiyeka okushisayo kuzobuyela esiteshini sokuqala kwesobunxele njengoba kungadinga.

Ijubane le-6.Shuttle

Ukulawulwa kwejubane lokushisa kwejubane elisheshayo nge-valve yejubane emzimbeni womshini - phansi kwesokudla

7.

Ukulawulwa kwe-Pedal ngesitenda esisodwa sokuthinta kunokuthinta okude.

8.Connector

Isixhumi se-Pedal Isixhumi kanye ne-Laser Alignment switch sitholakala emzimbeni womshini - ngaphambili

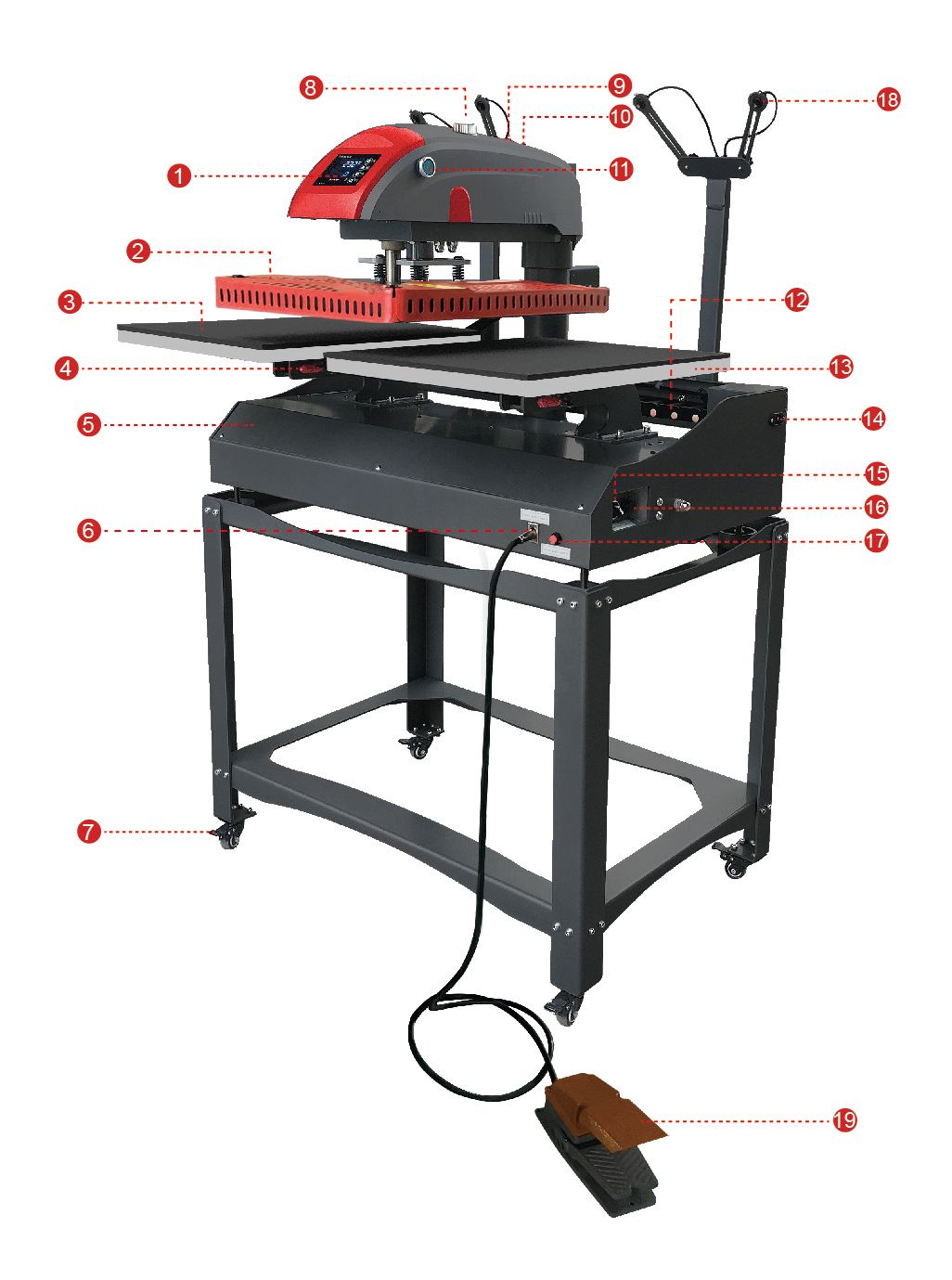

Isingeniso se-9.Machine Isingeniso

1. Ukulawula ukubonisa

2. Ukushisa Plater

3. I-Silicon Mat × 2

4. Idivaysi eshintshayo eshintshayo

I-5. Uhlaka lomshini

6. Ukushintsha kwe-Pedal

7. Brake caster

8. Inkinobho Yokukhishwa Okusheshayo

9. Ukushintshwa kwamandla

10. I-Thermal Breaker × 2

11. Inkinobho yokusebenza × 2

12. Iketanga lethangi

13. Iplate ephansi × 2

14. Ipulaki Power

15. I-Manual / Auto-Shintsha

16. I-Shuttle Speed Controller

17. Ukunikezwa kwamandla we-laser

18. Indawo yeLaser

19. Pedal

Isikhathi sePosi: Mar-03-2022

86-15060880319

86-15060880319 sales@xheatpress.com

sales@xheatpress.com